UTchem™

Corrosion-resistant process applications

Oilpeak is dedicated to enhancing various technologies, focusing on the application of corrosion-resistant materials in both dry and wet etching processes. These materials demonstrate excellent and stable properties when exposed to most organic solvents, acids, and alkalis.

Boilpeak’s perfluoroelastomer seals can withstand over 1,800 chemical media tests and offer superior sealing performance. This effectively reduces process defects and particle contamination. In semiconductor wafer manufacturing and other industries with highly corrosive chemicals, Boilpeak’s perfluoroelastomer seals provide exceptional chemical resistance, heat resistance, and ultra-high cleanliness. Additionally, in advanced nanotechnology processes, Boilpeak’s full range of products performs excellently, maintaining a leading position in the market.

Chemical resistance is high

With excellent chemical resistance, iteffectively extends the product’s lifespan

Global Compatibility

The products developed by Boilpeak are selected based on the continuously growing popularity of existing models.

Sealing Technology

Leading advanced processes to achieve next-generation nano high-purity sealing technology

Corrosion-resistant process applications

BOILPEAK has more than 10 years of excellent manufacturing experience, and keeps pace with the times with continuous development and innovation. Facing the harsh process conditions, we are committed to providing various solutions and continuously developing new special elastomer materials to provide the best sealing

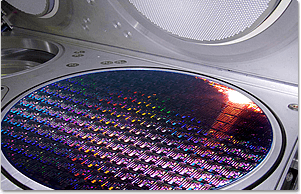

Thin Film Process

The thin film process can be divided into two deposition methods: CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition). Both deposition methods pose different challenges for sealing applications in the process.

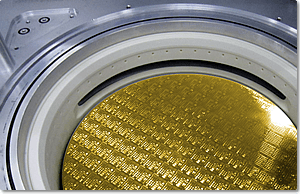

Etching Process

The etching process environment is categorized into Dry Etching and Wet Etching. The primary use of high-intensity plasma and various chemicals in the etching process poses different challenges for sealing applications.

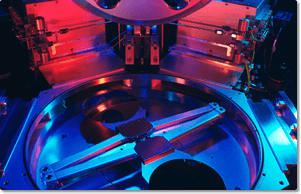

Diffusion Process

The diffusion process can be divided into Ion Implantation and Diffusion. The primary use of extremely high temperatures and various chemicals in the diffusion process poses different challenges for sealing applications.

High-purity product range

BOILPEAK extensively innovates O-rings and related products, working with customers to identify excellent combinations for industrial applications from China.

UTpure™ KS291

Product Features:

Excellent resistance to harsh chemical solvents

Extremely low metal ion content

Minimal residue in solvents

Good mechanical performance under low pressure

Product Applications:

Wet etching

Photolithography development

Wafer cleaning

Liquid pipeline transmission

Product Processes:Wet Etch、Pumpline、Filter

UTpure™ KS235

Product Features:

Excellent resistance to harsh chemical solvents

Extremely low metal ion content

Minimal residue in solvents

Good mechanical performance under low pressure

Product Applications:

Wet etching

Photolithography development

Wafer cleaning

Liquid pipeline transmission

Product Processes:Oxidation、Diff、ALD、LPCVD

UTpure™ KS732

Product Features:

High hardness, wear-resistant, and self-lubricating

Excellent plasma resistance

High-pressure sealing stability

Low gas permeability

Product Applications:

Gate valve seat sealing

Control valve / butterfly valve sealing

Dry etching chamber

Stop valve sealing ring

Product Processes:Dry Etch、PVD

UTpure™ KS130

Product Features:

Excellent plasma resistance

Sealing stability under high vacuum

Cost-effective with good economic benefits

Stable back pressure resistance

Product Applications:

CVD pipeline gas discharge

Plasma chamber sealing

Gas inlet and outlet sealing

Isolation valve sealing ring

Product Processes:Wet Etch、Dry Etch、Pumpline

UTpure™ KS291

Product Features:

Excellent plasma resistance

High-pressure sealing stability

Low gas permeability

High cleanliness

Product Applications:

CVD pipeline gas discharge

Plasma chamber sealing ring

Gas inlet and outlet sealing

Dry etching sealing ring

Product Processes:Dry Etch、PVD

UTpure™ KS291

Product Features:

High hardness, wear-resistant, and self-lubricating

Excellent plasma resistance

High-pressure sealing stability

Low gas permeability

Product Applications:

High vacuum etching chamber

Gate valve seat sealing

Control valve / butterfly valve sealing

Dry etching chamber sealing

Product Processes:Dry Etch、PVD