UTpure™

High Purity

The development of innovative technology and the spirit of relentless effort are the beliefs of Boilepak O-ring. Cleanliness is the key to technological breakthroughs in advanced processes and market competitiveness.

Boilpeak high-purity materials use patented polymerization technology, significantly improving the cleanliness of the product itself, and the manufacturing process does not require the addition of extra fillers. As a result, it ensures optimal cleanliness performance in most plasma environments, greatly improving process yield.

Additional fillers

Excellent physical properties without theneed for additional fillers

Global Compatibility

The products developed by Boilpeak are selected based on the continuously growing popularity of existing models.

Sealing Technology

Leading advanced processes to achieve next-generation nano high-purity sealing technology

Process Application

BOILPEAK has over 15 years of outstanding manufacturing experience, continuously developing and innovating in line with the times. In the face of demanding process conditions, we are committed to providing various solutions, continuously developing new specialty elastomer materials, and simultaneously offering the best sealing solutions.

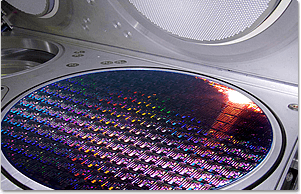

Thin Film Process

The thin film process can be divided into two deposition methods: CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition). Both deposition methods pose different challenges for sealing applications in the process.

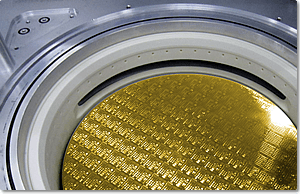

Etching Process

The etching process environment is categorized into Dry Etching and Wet Etching. The primary use of high-intensity plasma and various chemicals in the etching process poses different challenges for sealing applications.

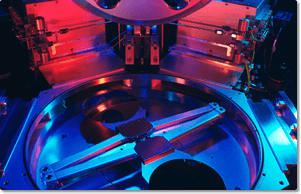

Diffusion Process

The diffusion process can be divided into Ion Implantation and Diffusion. The primary use of extremely high temperatures and various chemicals in the diffusion process poses different challenges for sealing applications.

High-purity product range

BOILPEAK extensively innovates O-rings and related products, working with customers to identify excellent combinations for industrial applications from China.

UTpure™ KS291

Product Features:

Good tolerance in O and F plasma environments

Excellent gas corrosion resistance in dry etching processes

Outstanding high-temperature resistance with very low outgassing rate

Excellent rebound and compression set performance

Product Applications:

Gas inlet and outlet sealing rings

Chamber cover sealing rings

Shut-off valve sealing rings

ATE valve and slit valve door seals

Product Processes:Etch、Tiff、CVD

UTpure™ KS235

Product Features:

Excellent plasma resistance

Outstanding high-temperature resistance

Extremely low outgassing rate

Excellent mechanical properties for dynamic and static sealing applications

Excellent ozone resistance

Product Applications:

Gas inlet and outlet sealing rings

Chamber cover sealing rings

Shut-off valve sealing rings

ATE valve and slit valve door seals

Product Processes:Etch、Tiff、CVD

UTpure™ KS732

Product Features:

Excellent resistance to F plasma

Good gas corrosion resistance in dry etching processes

Outstanding high-temperature resistance

Very low outgassing rate

Excellent rebound and compression set performance

Product Applications:

Bracket sealing washers

Filter sealing rings

Gate valve sealing rings

Isolation valve sealing rings

Product Processes:Etch、Tiff、CVD

UTpure™ KS130

Product Features:

Extremely high cleanliness with low contaminants

Excellent compression set performance

Very low metal ion content

Excellent performance in dry etching processes

Product Applications:

Gas inlet and outlet sealing rings

Transmission pipeline sealing rings

Bonded door panel sealing rings

Static sealing in low-seal, low-pressure applications

Product Processes:Etch、CVD

UTpure™ KS291

Product Features:

Extremely high purity with minimal contamination

Excellent resistance to O plasma erosion

Low gas corrosion weight loss

Outstanding compression set and rebound performance

Product Applications:

Chamber reaction room sealing rings

Observation window sealing rings

Gas inlet and outlet sealing rings

Clamp center bracket sealing rings

Product Processes:Etch、Pumpline

UTpure™ KS291

Product Features:

Extremely low metal ion content

Excellent resistance to chemical gases

Outstanding physical and mechanical properties

Excellent processing performance

Product Applications:

High-pressure chamber cover sealing rings

Pendulum valve sealing rings

Distributor sealing rings

Clamp center bracket sealing rings

Product Processes:Etch、Pumpline