UThot™

High temperature

Boilpeak perfluorinated elastomer seals are widely recognized as one of the best high-temperature resistant materials and are part of the most extensive fluorinated product series available in the market today. High-temperature and high-pressure environments are becoming increasingly common in advanced processes, and Boilpeak provides higher reliability under these demanding temperature conditions.

Heat resistance temperature

Utilizing patented polymerization technology, significantly improving cracking temperature resistance, and leading advanced high-temperature processes.

Global Compatibility

The products developed by Boilpeak are selected based on the continuously growing popularity of existing models.

Sealing Technology

Leading advanced processes to achieve next-generation nano high-purity sealing technology

High temperature resistant process

BOILPEAK has more than 10 years of excellent manufacturing experience, and keeps pace with the times with continuous development and innovation. Facing the harsh process conditions, we are committed to providing various solutions and continuously developing new special elastomer materials to provide the best sealing

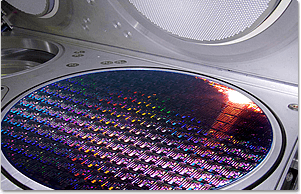

Thin Film Process

The thin film process can be divided into two deposition methods: CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition). Both deposition methods pose different challenges for sealing applications in the process.

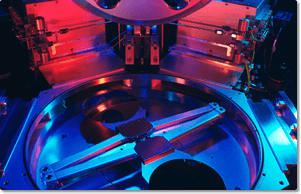

Etching Process

The etching process environment is categorized into Dry Etching and Wet Etching. The primary use of high-intensity plasma and various chemicals in the etching process poses different challenges for sealing applications.

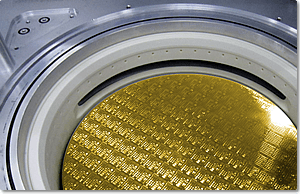

Diffusion Process

The diffusion process can be divided into Ion Implantation and Diffusion. The primary use of extremely high temperatures and various chemicals in the diffusion process poses different challenges for sealing applications.

High-purity product range

BOILPEAK extensively innovates O-rings and related products, working with customers to identify excellent combinations for industrial applications from China.

UThot™ KH215

Product Features:

Good high-temperature resistance

Excellent high-temperature steam performance

Outstanding mechanical properties

Good support and rebound force

Product Applications:

Center bracket sealing rings

Fluid transmission sealing rings

Filter sealing rings

Pipe gasket sealing rings

Product Processes:Wet Etch、Pumpline、Filter

UThot™ KH216

Product Features:

Wide high-temperature tolerance

Low gas outgassing rate at high temperatures

Low metal adhesion with no residue

Good high-temperature compression set performance

Product Applications:

Center bracket sealing rings

Quartz tube sealing rings

High-temperature chamber sealing rings

Observation chamber sealing rings

Product Processes:Oxidation、Diff、ALD、LPCVD

UThot™ KH218

Product Features:

Extreme high-temperature tolerance

Low gas outgassing rate at high temperatures

Slow thermal degradation at high temperatures

Good high-temperature compression set performance

Product Applications:

Center bracket sealing rings

Quartz tube sealing rings

High-temperature chamber sealing rings

Observation chamber sealing rings

Product Processes:Oxidation、Diff、ALD、LPCVD

UThot™ KH225

Product Features:

Good high-temperature resistance

Excellent high-temperature steam performance

Outstanding mechanical properties

Good support and rebound force

Product Applications:

Center bracket sealing rings

Fluid transmission sealing rings

Filter sealing rings

Pipe gasket sealing rings

Product Processes:Wet Etch、Pumpline、Filter

UThot™ KH126

Product Features:

Very good gas release rate

Excellent compression set performance

Outstanding high-temperature recovery performance

Non-adhesive to metal, ceramics, and quartz under low pressure

Product Applications:

Center bracket sealing rings

Quartz observation window sealing rings

Throttle valve sealing rings

Connector sealing rings

Product Processes:Oxidation、Diff、RTP

UThot™ KH791

Product Features:

Good tolerance in O and F plasma environments

Excellent gas corrosion resistance in dry etching processes

Outstanding high-temperature resistance

Very low outgassing rate

Product Applications:

Gas inlet and outlet sealing rings

Chamber cover sealing rings

Shut-off valve sealing rings

Dynamic sealing for gate valve and slit valve door seals

Product Processes:Oxidation、Diff、RTP